time:2020-12-08 browse:second

PT10SR-2511 pressure transmitter has the pressure chamber which is made of single stainless steel piece, and all-metal sealing structure. The transmitter adopts silicon microfusion technology and has specially designed structure. It uses the overall digital calibration and temperature compensation.

This transmitter can meet the OEM customers' large volume demand and is highly cost efficient. It can be widely used in air pressure, hydraulic, and even worse media measuring environment, such as sewage, steam, light corrosive gases and liquids and other industrial or civil field pressure monitoring. Special customized products for users are also available.

• Range: 0kPa~700kPa…100MPa

• Integrated stainless steel construction, full-sealed

• Micro-fused technology, heat-resistant, anti-shock

• Compact structure and cost-efficient

• Wide operating temperature range

| Pressure Range | 0kPa~700kPa…100MPa |

| Over-Pressure | 2×FS (max.150MPa); |

| Burst Pressure | 5×FS (max.200MPa); |

| Power Supply | 8V~28V DC or 5V DC |

| Output Signal | 4mA~20mA DC, 0.5V~4.5V DC |

| Accuracy | 1.0 rating |

| Compensation temp. | -10℃~80℃ |

| Operation temp. | -40℃~125℃ |

| Storage temp. | -40℃~125℃ |

| Medium Compatibility | All mediums that are compatible with 17-4PH stainless steel |

| Order Guide | ||||

| PT10SR-2511 | Presssure Transmitter | |||

| Range | 0kPa~700kPa…100MPa | |||

| [0~X]kPa or MPa | X: Actual measured range | |||

| Code | Output Signal | |||

| E | 4mA~20mA DC | |||

| K | 0.5V~4.5V DC | |||

| Code | Additional Function | |||

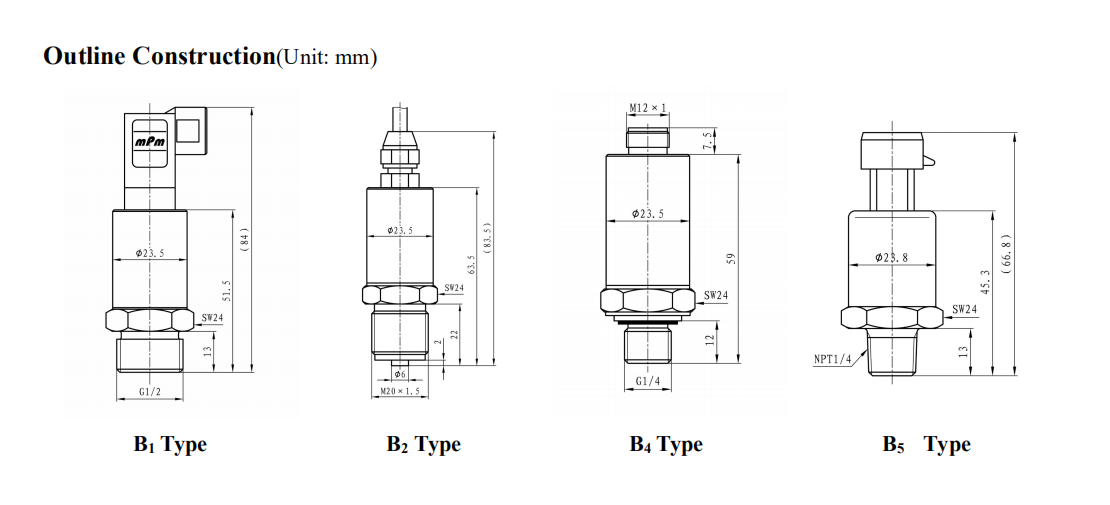

| B1 | 4 pin Plug(Mini Hirschmann) | |||

| B2 | Cable connection | |||

| B4 | 4 pin Plug(M12×1) | |||

| B5 | Packard Plug | |||

| C1 | M20X1.5 Male | |||

| C2 | G1/4 Male | |||

| C3 | G1/2 Male | |||

| C6 | NPT1/4 Male | |||

| C16 | G3/8 Male | |||

| PT10SR-2511 | [0~1.6]MPa | E | B1C1 | the whole spec. |

● Engineering machinery

● Hydraulic and pneumatic systems

● Energy and water treatment systems

● Refrigeration system

● Industrial process control and automatic detection system

● Pump or compressor

● Central air conditioning control system